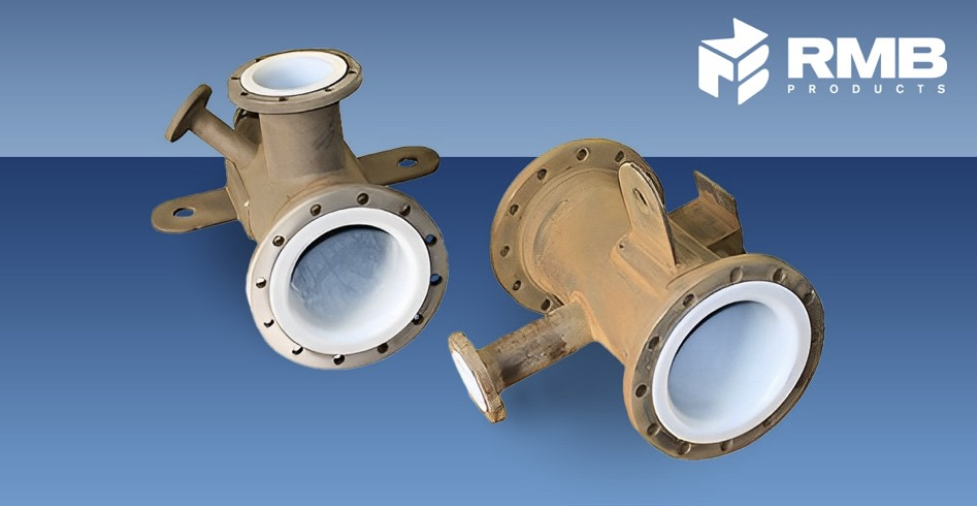

Rotational lining is a process where a liner is applied via a rotational molding process. However, a pipe, vessel, header, pump, etc. acts as the mold, and the liner is fully bonded to the metal substrate creating a fully bonded seamless liner. Thicknesses can range from 0.09” to almost ½” depending on the plastic used and the product’s service application.

A rotationally molded liner will eliminate or reduce the failure modes of almost every other lining or coating method available. RMB Products specializes in applying rotationally molded liners and has been doing so for over 20 years. Compared to powder coating, RMB’s liner is much thicker, slowing permeation and providing better abrasion resistance. A sheet liner will require an adhesive which can limit the liners service temperature and fail under vacuum. A sheet also requires numerous plastic weld seams which can be quicker paths for permeation. A rotomolded liner eliminates the need for plastic welding and adhesives. It can withstand most vacuum services. The mechanical bond strength achieved by blasting the metal to white metal prior to lining is greater than the tensile strength of the plastic material. Compared to glass, RMB’s liner is repairable if it is damaged due to physical impact. A loose sleeve liner will have space between the metal substrate and liner in which chemicals can pool and cause corrosion. There is no space behind a fully bonded rotomolded liner.

Using a rotationally molded liner from RMB Products, a customer can expect longer service life’s compared to the coatings or linings they may have used in the past.