Expanding Horizons: Harnessing Laser Sintering's Potential for Industry

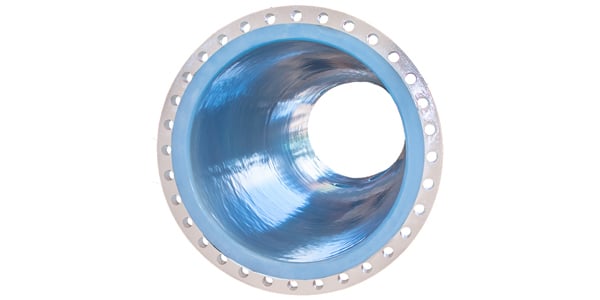

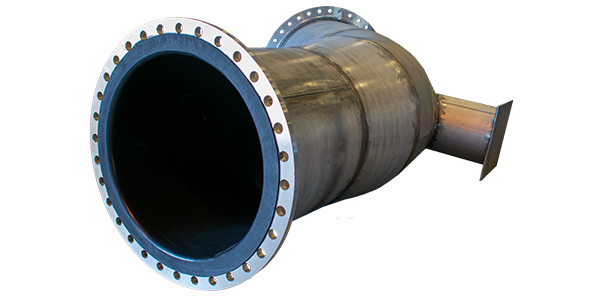

As additive manufacturing continues to revolutionize industries, laser sintering is breaking free from its aerospace roots — one of the first business segments to embrace and benefit from its...READ MORE