Why Tank Linings Matter: Choose ETFE for Superior Corrosion Protection

It's 3 a.m. when your emergency alert sounds. A glass-lined reactor vessel processing hydrochloric acid has developed a crack and the corrosive chemicals within are now attacking the steel substrate. Production grinds to a halt and although maintenance is swift to respond, the damage is done. Your team estimates the vessel will be out of commission for weeks, months, as you navigate repairs or replacement. This scenario plays out regularly in chemical processing facilities when tank linings fail, leading to unplanned downtime, safety risks, and significant financial losses.

Navigating your options: A guide to tank lining selection

Current tank lining options include:

- Glass lining. While noted for its chemical resistance, glass lining is notorious for its brittleness and challenging repairs. When cracks develop, repairs can lead to extensive downtime, and the fragile nature of the material means facilities must exercise extreme caution during maintenance and operation to prevent damage.

- Rubber lining. Though offering the advantage of on-site repairs, rubber lining typically fails within 5-10 years of service. The material gradually deteriorates as service conditions take their toll, allowing chemicals to penetrate behind the lining. This leads to the corrosion of the steel substrate, and oftentimes the lining will detach from the substrate along the adhesive line, requiring complete replacement. This material and on-site application method, however, often provide a solution for tanks or vessels that must remain on-site or are in sites with tight or difficult access.

- Fiberglass-reinforced plastic (FRP) or dual-laminate equipment. These present facilities with another option that can be field fabricated or repaired on-site. While this method might present a lower initial cost, this style lining also comes with complex application requirements and potential delamination issues. The multilayer nature of these systems creates weak points where chemical attack can occur, particularly at joints and transitions.

- PTFE lining. Despite excellent chemical resistance, PTFE linings have temperature-related limitations and can exhibit cold flow issues (movement related to thermal changes). Field repairs are limited, and the material may deform under certain operating conditions, potentially compromising the lining's integrity.

- ETFE rotational lining (rotolining). Though offering superior chemical resistance and a uniform, void-free barrier, ETFE rotolining has size limitations based on available equipment for application, such as oven size. In addition, field repairs are not possible. However, its extended service life, chemical resistance properties, and temperature range make it an attractive choice for chemical processing equipment that can be transported to RMB Products’ facility for rotolining.

The choice between these options often depends on specific facility requirements, maintenance capabilities, and long-term operational goals.

Quick reference: Tank lining comparison

| Lining Type | Key Benefits | Primary Limitations |

|---|---|---|

| Glass | High chemical resistance | Brittle, difficult repairs |

| Rubber | Possibility of on-site repairs | 5- to 10-year lifespan |

| FRP/Dual Laminate | Lower initial cost | Complex application, delamination risk |

| PTFE | Excellent chemical resistance | Permeation |

| ETFE | Superior longevity, uniform protection | Size limitations, no field repairs |

| PFA | High purity and chemical resistance | Requires weld seams for installation |

ETFE for the next evolution in corrosion protection

Ethylene tetrafluoroethylene (ETFE) represents the forefront of corrosion protection technology. This engineered fluoropolymer delivers exceptional chemical resistance combined with outstanding mechanical properties, creating an impermeable barrier against aggressive chemicals while maintaining structural integrity under demanding process conditions. When applied through rotolining, ETFE forms a seamless, highly adherent protective barrier that outperforms traditional lining options.

But making the switch to ETFE is not always straightforward. According to empirical industry evidence, about 75% of tank lining projects involve replacing existing equipment in established processes, while only 25% are new installations. This reality means most engineers face a critical decision: stick with familiar technology or embrace a more advanced solution.

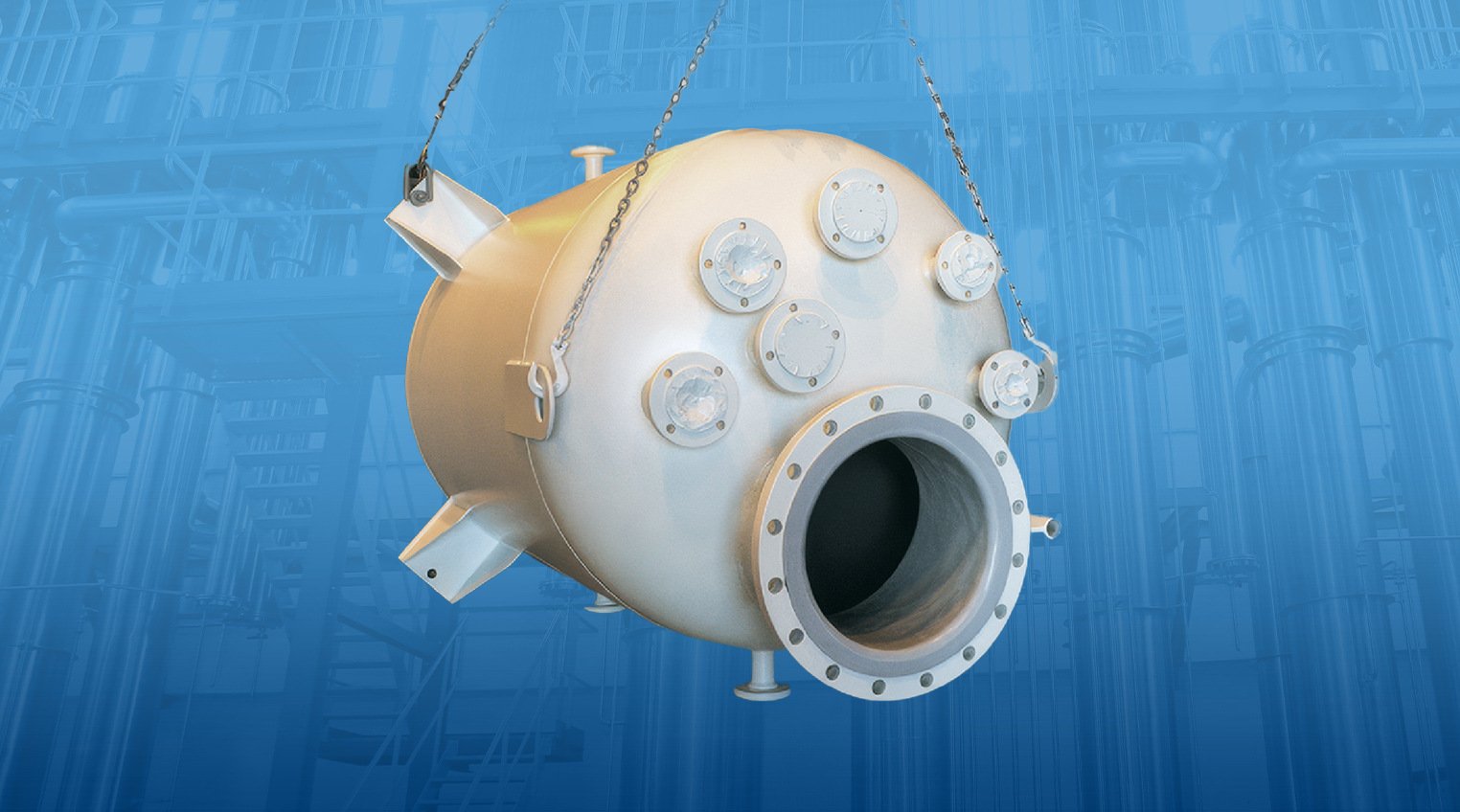

Rotolining: How advanced engineering supplies superior protection

Rotolining represents an advanced application method for ETFE that creates a seamless, highly adherent protective barrier. The process involves rotating the vessel while heating the fluoropolymer resin to its melting point, allowing it to form a uniform, void-free lining that bonds directly to the metal substrate. This technique ensures comprehensive coverage, including complex geometries and internal structures, while eliminating the weak points often associated with other lining methods.

What makes rotational lining particularly effective is its ability to create consistent coverage even in complex vessel geometries. During the rotation process, the multiaxis movement combined with precise temperature control ensure the ETFE polymer flows evenly across all surfaces, including corners, welds, and internal structures. This uniform distribution is crucial for long-term performance, as it eliminates thin spots or excess buildup that could become failure points under aggressive chemical exposure. The controlled factory environment where rotolining takes place also ensures optimal conditions for the polymer-to-metal bonding process, resulting in superior adhesion compared to field-applied alternatives.

Making the transition to ETFE for tank linings

ETFE as the polymer selected for rotolining of chemical processing tanks, offers several distinct advantages:

- Superior Longevity: Compared to traditional options like rubber lining (5-10 years), ETFE linings provide extended service life with minimal degradation.

- Uniform Protection: The rotolining process ensures consistent coverage and thickness, eliminating weak points common in other lining systems.

- Enhanced Safety: The seamless, bonded lining minimizes the risk of chemical penetration and subsequent corrosion of the substrate.

- Quality Assurance: For ASME Section 8 code-stamped vessels, ETFE lining processes can be fully integrated with required quality control protocols and documentation requirements.

- Maintenance Efficiency: While field repairs may not be possible, the durability and reliability of ETFE linings often result in reduced maintenance requirements over the vessel's lifetime.

Generational perspectives on tank protection

A significant transformation is occurring within the industry as younger engineers bring fresh perspectives to equipment decisions. These emerging professionals demonstrate a greater willingness to innovate and create value through innovative solutions. Their approach typically involves comprehensive research into alternative technologies, the development of detailed comparison spreadsheets examining multiple options, and thorough analysis of benefits, drawbacks, pricing, and timing considerations. Rather than relying on historical preferences, they embrace data-driven decision-making processes that often lead to discovering more efficient solutions.

Planning for success: Timeline and project management considerations

Project planning requires careful consideration of multiple time factors. Initial engineering and drawings typically require 3-5 weeks to complete, followed by 8-14 weeks of standard fabrication time after drawing approval. While emergency replacements can be expedited to 5-6 weeks in critical situations, multi-tank orders often require extended timelines to ensure quality and proper execution. Most customers plan 6 months to a year ahead for major vessel projects, though ETFE providers generally offer more agile timelines than competitors in the glass-lined or dual-laminate space.

Organizations considering ETFE-lined vessels should plan implementation carefully:

- Lead time planning. Typical projects require 8-14 weeks from approved drawings to shipping, with emergency replacements possible in 5-6 weeks.

- Quality control. For code-stamped vessels, expect comprehensive documentation, material tracing, and inspection requirements.

- Size limitations. Vessel dimensions must be compatible with rotolining equipment capabilities.

- Capital investment. While initial costs may be higher than some alternatives, the extended service life and reduced maintenance requirements often provide favorable long-term economics.

For ASME Section 8 code-stamped vessels, ETFE rotolining projects receive meticulous oversight throughout the entire process. Customers should be aware that the ASME quality standards lengthen the timeframe for project completion. The steps should include:

- Engineering calculations must receive authorized inspector approval before proceeding with any work.

- Material tracing certifications must accompany all components to ensure compliance and quality standards.

- Customer source inspections occur at critical stages.

- Radiographic verification of structural integrity ensures the highest levels of safety and reliability.

Specific quality control protocols guide each step of the manufacturing process at RMB, supported by comprehensive documentation requirements.

Future-proofing facilities with modern inspection and maintenance protocols

Modern chemical processing facilities are rapidly evolving their approach to equipment maintenance and inspection. Remote monitoring capabilities and non-destructive testing methods are becoming standard practice, while facilities seek to reduce confined space entry requirements and extend service intervals between inspections. Some organizations have implemented zero confined space entry policies in response to safety concerns, driving increased demand for exceptionally reliable linings that minimize inspection and maintenance requirements. ETFE's exceptional durability aligns perfectly with these evolving safety protocols, offering long-term reliability with minimal intervention requirements.

Most customers plan 6 months to a year ahead for major vessel projects. While this might seem long, ETFE providers often offer more nimble timelines than competitors in the glass-lined or dual-laminate space.

The choice ultimately comes down to balancing immediate comfort against long-term performance. As younger engineers bring fresh perspectives and data-driven decision-making to the industry, ETFE's advantages become increasingly compelling for organizations focused on future-proofing their operations.

Balance immediate performance needs with long-term goals

Selecting the appropriate lining technology for process vessels requires careful evaluation of technical, operational, and organizational factors. While traditional solutions may offer familiarity and established maintenance protocols, ETFE rotolining provides compelling advantages in terms of longevity, performance, and overall value. Forward-thinking organizations increasingly recognize these benefits, particularly when considering total lifecycle costs and operational reliability requirements.

For engineering teams evaluating corrosion protection options, ETFE represents a strategic choice that balances immediate performance needs with long-term operational goals. Success in implementation often comes from early engagement with suppliers, thorough planning, and clear understanding of both technical requirements and organizational constraints.

Request a quote from RMB to get started with your next corrosion-resistant tank project.